RFID tags have changed inventory management and supply chain operations in the current technology-driven market. As businesses seek new ways to reduce errors, improve efficiency, and gain better control over their stock, RFID technology has come up as an important solution.

From tracking merchandise to optimizing inventory levels, RFID tags simplify operations and enhance accuracy across multiple industries. But what exactly are RFID tags, and how do they work? This extensive guide explores how RFID tags are used in retail, supply chain management, and other sectors. They help businesses optimize operations and improve profitability.

At FineLine, we pride ourselves on delivering high-quality RFID tags, labels, and packaging to help businesses with their identification and tracking needs. Our custom variable-data products can be delivered in under 48 hours and paired with automation options to guarantee seamless integration of tagging solutions into your supply chain. We help enable clients to improve accuracy and accelerate their operations. Let’s look in-depth into RFID technology and its practical uses.

Understanding RFID Tags

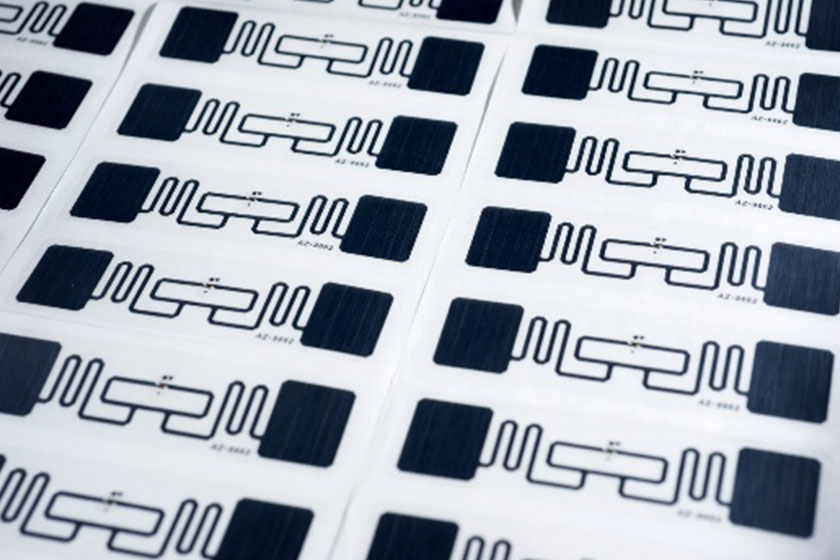

Radio Frequency Identification (RFID) tags are comprised of a chip and an antenna. These two parts allow them to communicate wirelessly with RFID readers. Unlike traditional barcodes, RFID tags do not require direct line-of-sight scanning. This makes them a more efficient and versatile option for tracking and identifying items. RFID tags work through electromagnetic fields, which transfer data between the tag and the reader.

The primary function of an RFID tag is to store unique identification data that can be read by RFID systems. This data allows businesses to track individual items in real time. They can provide more accurate information about stock levels, product locations, and movement through the supply chain. Whether used in retail, healthcare, automotive, or manufacturing, RFID tags offer an efficient way to manage inventory and assets.

Our RFID tags are made with flexibility in mind. They offer solutions that cater to a wide range of industries and business needs. From apparel tagging to specialized RFID labels for automotive parts, we help businesses enhance their tracking systems. Every item can be accurately identified and accounted for.

Types of RFID Tags

There are two main types of RFID tags: active and passive. Each type operates differently and is suited for specific use cases, depending on the requirements of the business or industry.

Active RFID Tags

Active RFID tags are equipped with an onboard battery that powers the tag’s microchip and antenna. Because of their built-in power source, active RFID tags continuously transmit signals. This allows them to be read over long distances—sometimes up to several hundred feet. This makes them ideal for real-time tracking applications such as vehicle tracking, tolling systems, and cargo monitoring.

Active RFID tags are larger and more durable than passive RFID tags. They are more suitable for use in harsh environments. However, they are also more expensive due to the battery and larger form factor. The battery in an active RFID tag typically lasts between three to five years, after which the entire unit must be replaced.

Passive RFID Tags

Unlike active RFID tags, passive RFID tags do not have an internal power source. Instead, they rely on the energy transmitted from the RFID reader to power the tag. This makes passive RFID tags smaller, lighter, and less expensive than their active counterparts. However, the trade-off is that passive RFID tags have a much shorter read range, usually between a few inches to several feet.

Passive RFID tags are commonly used in applications such as inventory management, access control, and asset tracking. These are applied situations where the short read range is not a limitation. They are highly cost-effective, making them ideal for tracking large volumes of items.

How RFID Tags Are Used in Various Industries

RFID tags are used in a wide variety of industries and applications, thanks to their versatility and ability to optimize operations. Below are some of the most common use cases for RFID tags.

Event Mangement

RFID tags are often used as electronic keys to control traffic access for large events. For example, concert venues may issue RFID-enabled tickets. This can grant customers access to specific areas within the event. It provides an additional layer of security and allows event venues to track customer’s movements for traffic control and safety purposes.

Asset Tracking

RFID tags are commonly used for tracking high-value assets, such as equipment, vehicles, and tools. Attaching RFID tags to these items enables businesses to prevent theft, reduce loss, and ensure that assets are readily available when needed. This is especially important in industries like construction, manufacturing, and logistics, where equipment downtime can be costly.

Food

In the food industry, RFID is a powerful tool for enhancing food safety and traceability throughout the supply chain. By tracking products from production to the consumer, RFID provides precise, real-time data that ensures food safety standards are met at every stage. RFID tags can monitor temperature conditions during transportation and storage, helping prevent spoilage and contamination. Additionally, RFID helps reduce waste by tracking expiration dates, enabling quicker response to items nearing the end of their shelf life, which is essential for maintaining high standards of quality and safety for consumers.

How Are RFID Tags Used in Retail?

One of the most prominent industries utilizing RFID technology is retail. Retailers use RFID tags primarily for inventory accuracy. It allows them to track products from the moment they are tagged by the vendor to when they are sold in stores or online.

The retail supply chain is complex, involving various channels like brick-and-mortar stores, online platforms, and warehouses. RFID tags help simplify this process by offering a more efficient way to manage stock.

The tagging process typically begins when vendors receive RFID hang tags or RFID labels. Vendors then apply these tags to their merchandise before shipping the products to the retailer. Once the products are delivered, retailers use RFID readers to scan and count inventory. This ability to count items using RFID technology significantly improves the speed and accuracy of stock assessments.

For example, in traditional barcode-based systems, retail inventory accuracy tends to hover around 65%. However, with RFID technology, this accuracy jumps to over 95%. This way, retailers are able to maintain more reliable stock levels.

With more accurate data, retailers can offer a wider range of services such as buying online, picking up in-store, or shipping from store options without worrying about stock discrepancies. Making more merchandise available online and reducing the need for markdowns allows retailers to increase profits while offering a better customer experience.

The Role of RFID in Inventory Accuracy

Inventory accuracy is a key metric that influences a retailer’s ability to meet customer demand, reduce stockouts, and avoid excess inventory. RFID technology is important in improving inventory accuracy by providing real-time visibility into stock levels.

Unlike barcodes, which require manual scanning of each item, RFID readers can scan multiple items simultaneously. This eliminates the need for labor-intensive manual counting processes.

At FineLine, we provide RFID tags that guarantee reliable, item-level identification. Our RFID tags are used by retailers to count stock more frequently. They enable better demand forecasting, stock replenishment, and inventory management. Using RFID enables retailers to maintain optimal stock levels across stores and warehouses, reducing the risk of stockouts and improving operational efficiency.

RFID technology also enables better inventory auditing. Since RFID systems automatically log stock data as items move through the supply chain, retailers can quickly identify discrepancies. This can include missing items or misplaced stock. This real-time data helps businesses address potential issues before they escalate for inventory accuracy and to prevent financial losses.

What Data Is Encoded on RFID Tags?

A common question among businesses is what specific data is stored on RFID tags. In the retail industry, most RFID tags follow the SGTIN-96 encoding format. SGTIN stands for Serialized Global Trade Item Number. This combines a product’s Global Trade Item Number (GTIN) with a unique serial number. The GTIN is essentially the same as the barcode number, while the serial number allows each item to be uniquely identified.

This setup is especially beneficial for managing large quantities of similar items. For instance, a retailer may have hundreds of identical sweaters, each with the same GTIN. Using RFID tags with unique serial numbers allows the retailer to track and count each sweater individually at the item level. This level of specificity allows for more detailed stock tracking and enables retailers to monitor individual items from production to sale.

While the SGTIN-96 format is the most commonly used, we offer flexibility in how the data is structured based on our clients’ needs. It is important to note that RFID tags only store limited information, such as the product’s GTIN and serial number. Other details like product name, size, price, or purchase order number are typically printed on the physical hang tag or sticker but are not encoded in the RFID tag itself.

RFID Technology in Supply Chain Management

RFID technology is not limited to retail; it is important in supply chain management across various industries. Supply chains involve multiple stages, from manufacturing and distribution to warehousing and retail. RFID tags help optimize these processes by providing real-time data on the movement and location of goods throughout the supply chain.

For businesses that rely on efficient logistics and delivery, RFID offers a solution to manage and track inventory with greater accuracy. Implementing RFID systems allows businesses to reduce the time spent manually scanning and tracking goods. Instead, RFID readers can instantly scan all items within range. They make it easier to track shipments, manage inventory levels, and make sure that products are delivered on time.

In addition to tracking stock movement, RFID technology provides valuable analytics. RFID systems can generate detailed reports on product flow, stock levels, and sales trends. They can help businesses refine their supply chain strategies. RFID data helps businesses make informed decisions that improve efficiency and reduce costs.

Advantages of RFID Tags Over Barcodes

While barcodes have long been the standard for product identification, RFID tags offer several advantages that make them a superior solution for many applications. One of the main differences between RFID tags and barcodes is that RFID does not require direct line-of-sight scanning. This makes RFID systems faster and more efficient. They can read multiple tags simultaneously without needing to scan each item individually.

Another advantage of RFID technology is its ability to store more data. While barcodes are limited to a simple number that identifies the product, RFID tags can store both the product identifier and a unique serial number. This allows for item-level tracking, giving businesses more granular control over their inventory.

RFID tags offer several other advantages over traditional tracking methods, such as barcodes. Some of the key benefits of using RFID tags include:

- Increased Efficiency

RFID tags allow for faster and more efficient tracking of items compared to manual barcode scanning. This is especially useful in industries where speed and accuracy are important, such as retail.

- Improved Accuracy

RFID tags improve inventory accuracy by enabling real-time, automated scanning without needing direct line-of-sight, unlike barcodes. This reduces human error and accelerates stock updates, improving overall inventory accuracy.

- Reduced Labor Costs

Since RFID tags can be read automatically, businesses can reduce the need for manual labor associated with inventory counts and asset tracking. This can lead to significant cost savings, especially in industries with large volumes of items to track.

- Enhanced Security

RFID tags can be encrypted and programmed with unique identifiers. This makes it more difficult for counterfeit or unauthorized items to enter the supply chain. This is particularly important in industries like pharmaceuticals and automotives, where product authenticity is critical.

- Real Time Tracking

RFID technology allows for real time tracking of items, providing businesses with up-to-date information on the location and movement of their inventory. This improves supply chain visibility and helps businesses respond more quickly to changes in demand or inventory levels.

Future Trends in RFID Technology

As technology continues to progress, the future of RFID is promising. New innovations are on the horizon that will further enhance its capabilities. One of the key areas of growth is in the realm of monitoring environmental conditions. The integration of RFID tags enables real-time tracking of not only product location but also critical environmental factors like temperature, humidity, and air quality. This combination allows businesses to ensure optimal conditions for sensitive goods such as food and pharmaceuticals, enhancing supply chain visibility and reducing the risk of spoilage.

We are constantly innovating to stay ahead of these trends. We continue to explore new ways to enhance our RFID solutions. From launching the first RFID quality control app on the market to developing new applications for RFID in retail and logistics, we are committed to helping businesses unlock the full potential of RFID technology.

Custom RFID Solutions for Business Needs

Every business has its own set of challenges when it comes to inventory management and product identification. We offer custom RFID products and solutions to address these specific needs. Whether you are tagging high-value goods, managing complex supply chains, or dealing with hard-to-tag products, our RFID solutions provide the flexibility and performance required.

For retailers, we provide custom RFID hang tags, labels, or packaging that meet the requirements of their merchandise and branding. Our team works closely with clients to guarantee that RFID tags are easily integrated into their packaging and labeling strategies. This not only improves tracking but also enhances the visual appeal of the products.

For industries like automotive, where tagging can be particularly challenging, we offer RFID tags for specialty items like tires, automotive parts, and other hard-to-tag goods. These tags are built to withstand extreme conditions while maintaining accurate tracking capabilities.

Additionally, our FASTtrak platform promises that businesses can monitor their RFID orders in real time. This gives them complete control over the tagging process. With our industry-leading 48-hour turnaround time, businesses can rely on us for fast, accurate, and reliable RFID products.

RFID tags are reshaping how businesses manage their inventory, supply chains, and customer experiences. By offering faster, more accurate tracking, RFID technology helps businesses improve efficiency and enhance overall operational performance. At FineLine, we take pride in delivering top-quality RFID tags, labels, packaging, and solutions to help businesses stay competitive in today’s market.

Our expertise in RFID technology, combined with our commitment to customer service, guarantees that businesses receive the best solutions for their needs. Whether you need RFID tags for retail, automotive, food, or industrial applications, we are your trusted partner. Our custom solutions, fast delivery times, and innovative FASTtrak platform make us a leader in the RFID industry.

Ready to take your inventory management and supply chain operations to the next level? Contact us today to learn how our RFID solutions can help you improve accuracy, efficiency, and profitability.