Barcodes work tirelessly behind the scenes to keep supply chains moving, inventories accurate, and operations efficient. They have transformed how businesses track products, manage assets, and gather data. Yet, many overlook that barcodes come in different forms. The debate between 1D vs. 2D barcodes goes far beyond aesthetics or size. It’s about using the right tools to achieve operational success.

Barcodes do more than just speed up checkout lines. They manage work-in-process tracking, control inventory, and even boost cost savings by simplifying operations. Understanding the distinctions of 1D and 2D barcodes becomes important as supply chains grow more complex. These two types of barcodes serve distinct roles. They are driven by their data capacity, structure, and the technology that reads them.

This article will explore what sets these barcode types apart, where they excel, and how they fit into various industries. First, let’s dig into the foundation of barcoding technology.

The Foundation of 1D vs. 2D Barcodes

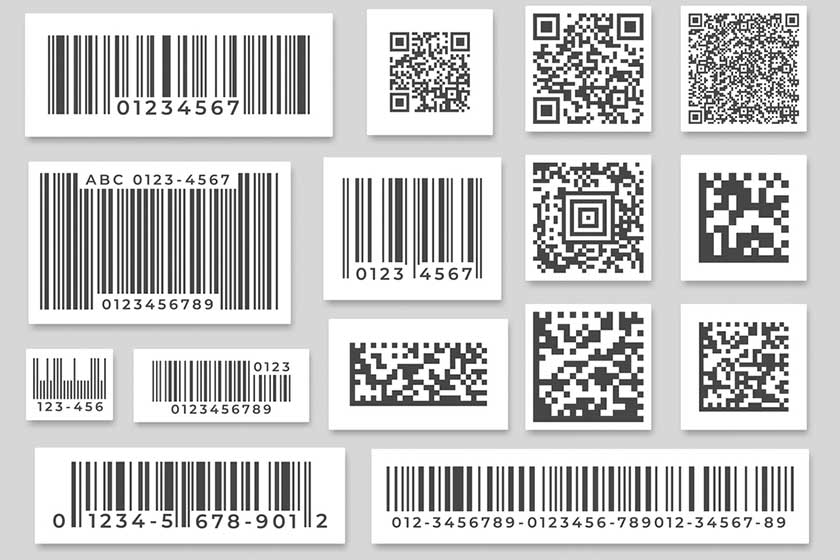

At its core, a barcode encodes data visually. It translates the data into patterns that machines can read. This technology has been a game-changer for businesses tracking assets, monitoring inventory, and automating workflows. Barcodes often include details like product origin, manufacturing date, and price. While 1D and 2D barcodes perform these tasks, their structure and capabilities differ significantly.

A 1D barcode is known as a linear barcode. It uses a series of vertical lines and spaces to encode data horizontally. These barcodes are highly recognizable and widely used in retail environments. They typically store up to 85 information characters. This makes them suitable for applications requiring basic data.

In contrast, 2D barcodes take data storage to another level. These advanced codes store information horizontally and vertically. It allows them to hold UP TO thousands of characters. From web links to encrypted data, 2D barcodes provide versatility. Their compact size and self-contained data structure make them ideal for industries with tracking needs.

The Role of 1D Barcodes

Despite the rise of 2D barcodes, 1D barcodes remain prevelant in many industries. Their simplicity and efficiency make them a core aspect of retail, where they are often found on product packaging. When scanned, they link to external databases that store additional information like stock levels and pricing. This integration supports fast and accurate inventory management.

Industries relying on durability also benefit from 1D barcodes. These labels withstand wear and tear in industrial environments. It helps data remain accessible even when barcodes are damaged. Tracking industrial equipment, lab specimens, or automotive parts often requires the straightforward reliability of 1D barcodes.

Additionally, 1D barcodes are easy to integrate into existing systems. Businesses commonly use laser scanners to read these codes. Their cost-effectiveness makes 1D barcodes practical for businesses prioritizing affordability and simplicity.

The Potential of 2D Barcodes

The versatility of 2D (2-dimensional) barcodes reshapes how industries track and manage assets. These barcodes use a combination of dots, squares, and other patterns to store significantly more data. A QR code is a type of 2D barcode that is widely used by marketers, businesses, and event organizers in campaigns, product tracking, and ticketing systems. A Data Matrix code is a specific type of 2D barcode that is frequently used in the food industry to monitor “sell-by” dates. Evidently, 2D barcodes are gaining traction in supply chains. This is due to their ability to embed URLs, product specifications, and expiration dates.

Another key advantage is the speed and flexibility of scanning 2D barcodes. Unlike 1D barcodes, they don’t need to be aligned in a specific direction for scanners to read them. Camera-based imaging scanners can decode these codes quickly. Hence, they are ideal for high-speed assembly lines and logistical hubs.

2D Barcodes in the Retail Industry

In retail, 2D barcodes are becoming increasingly important for improving efficiency and data accuracy across the retail supply chain. Unlike traditional 1D barcodes, 2D barcodes can store significantly more information, allowing retailers to enhance product tracking, inventory management, and customer engagement. With the upcoming Sunrise 2027 [link to blog] initiative, the industry is moving towards the adoption of 14-digit Global Trade Item Numbers (GTINs) encoded in 2D barcodes, marking a major shift in how products are identified and scanned at retail locations. This transition aims to streamline operations and also provide more detailed product data, improving both the consumer experience and supply chain visibility.

How Technology Shapes Barcode Applications

The differences between 1D and 2D barcodes go hand in hand with the technology used to read them. 1D barcodes rely on laser scanners. These scanners are precise and affordable for applications involving linear codes. However, 2D barcodes require camera-based imaging scanners. They are more advanced and capable of decoding complex patterns. With the Sunrise 2027 initiative, retailers will be required to use 2D barcodes at the point of sale, improving inventory management, overall supply chain efficiency, and enabling new use cases such as consumer engagement, product authentication, receipt-less returns, and more.

This shift in technology expands the potential of barcodes. For example, industries with stringent compliance requirements benefit from integrating 2D barcodes with advanced scanners. These systems track components, provide detailed product histories, and maintain compliance with safety standards.

We Are the Right Partner for Your Barcode Needs

At FineLine, we specialize in high-quality barcode ticket and label services that help businesses optimize operations. Whether you need 1D or 2D barcodes, our products are built for precision, durability, and efficiency. Our reliable barcode products and proprietary data management platform, FASTtrak, ensures seamless tracking and management of your barcode data.

And as industries prepare for Sunrise 2027, we are ready to support the transition to 2D barcodes, ensuring compliance with new standards. With expertise in custom branding, integrated packaging, and the fastest turnaround times in the industry, we provide barcode solutions tailored to your needs.

Contact us today to find the perfect barcode ticket and label solution for your business.